CHEMIKAL STATES LLC

Rust Converter - Stop Corrosion

Rust Converter - Stop Corrosion

5.0 / 5.0

(14) 14 total reviews

- Tax will be applied at checkout.

- Courier Delivery Costs:

- The cost of courier delivery is $7.

In stock

Couldn't load pickup availability

Rust Neutralizer / Rust Protector – Your Best Ally in the Fight Against Corrosion!

How to apply Rust Converter:

- Shake the canister before use.

- Remove loose rust.

- Apply the product to the rust.

- Wait for the rust neutralizer to dry.

- Paint over it or use another anti-corrosive treatment.

Features

The Chemikal States Rust Neutralizer / Rust Stopper is a cutting-edge product that:

- Effectively removes rust from various metal surfaces.

- Protects against future rust by creating a durable protective barrier.

- Works quickly and efficiently, delivering visible results after the first application.

Benefits

By choosing Rust Neutralizator, you gain:

- Time and money savings: no need to replace rusty parts – simply use our rust neutralizer.

- Ease of use: the product is simple to apply, requiring no special tools or skills.

- Long-lasting results: with its advanced formula, you can protect metal surfaces for an extended period.

Differentiators

The Chemikal States Rust Treatment stands out for:

- Innovative formula: developed using the latest chemical technology for maximum effectiveness.

- Safety: the product is safe for users and the environment, with all necessary certifications.

- Versatility: perfect for both home and professional use.

Don’t let rust ruin your metal surfaces. Choose the Rust Inhibitor and enjoy long-lasting protection and a pristine look for your metals!

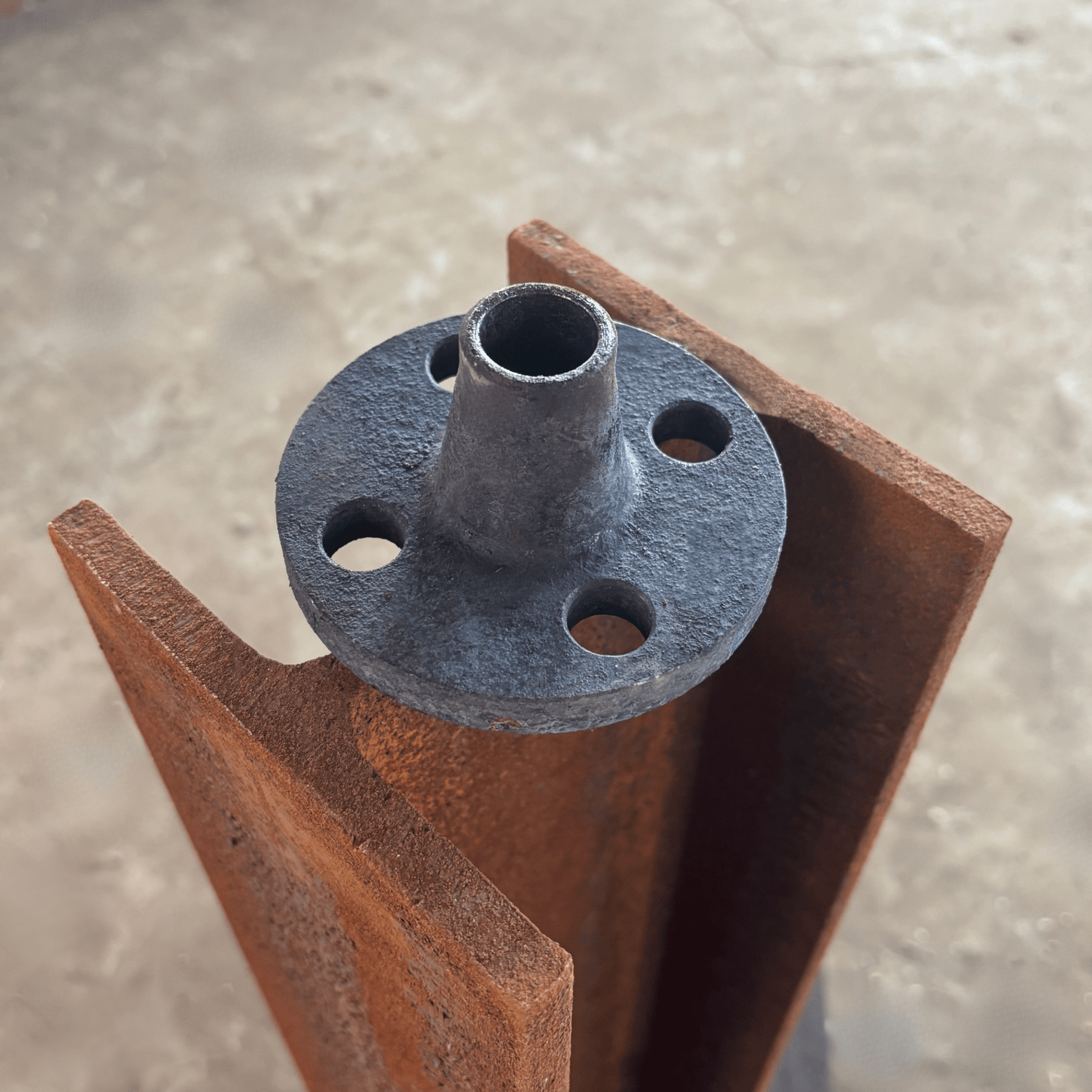

Description: Corrosion Converter is a powerful solution designed to neutralize rust and prevent further corrosion on metal surfaces.

Chemical Composition: Contains proprietary inhibitors.

Applications:

- Suitable for use on iron, steel, and other ferrous metals.

- Apply directly to rusted surfaces. Ensure the surface is clean and dry before application.

- Allow to dry for 24 hours before applying any topcoat.

Properties:

- Highly effective in neutralizing rust.

- Eco-friendly and non-toxic.

- Water-resistant and weather-resistant.

Technical Specifications:

- Density: 1.2 g/cm³

- pH: 5.0

- Operating Temperature: 41°F to 77°F

- Coverage: 215 square feet per 27 fluid ounces

Precautions:

- Wear protective gloves and eyewear during application.

- Store in a cool, dry place away from direct sunlight.

- In case of contact with skin or eyes, rinse immediately with plenty of water.

Packaging:

- Available in 27 fl oz.

- Packaged in recyclable plastic bottles.

Storage and Shelf Life:

- Store at temperatures between 41°F and 77°F.

- Shelf life: 5 years from the date of manufacture.

Safety Instructions for Rust Converter

Product Description:

The rust converter contains 4% corrosion inhibitors, which are not classified as hazardous substances under current regulations.

General Safety Instructions:

- Use the product according to the instructions on the packaging.

- Avoid contact with eyes and skin.

- In case of eye contact: Carefully rinse eyes with water. If symptoms persist, seek medical advice.

- In case of skin contact: Wash with plenty of water and soap. If irritation occurs, consult a doctor.

- Keep the product out of reach of children.

Storage:

Store the product in a well-ventilated area, away from direct sunlight and frost.

Disposal:

Unused quantities and empty containers should be disposed of in accordance with local regulations.

First Aid Measures:

- If swallowed: Do not induce vomiting. Rinse mouth and immediately seek medical attention.

- If inhaled: Move the affected person to fresh air and keep them in a position that facilitates breathing.

These safety instructions have been prepared to comply with local regulations.

Share

SKU:rustconverter59

View full details

How it works?

Why Choose Our Product?

1. Effectiveness and Versatility

- Immediate Action: Our rust neutralizer starts working right after application, so you don’t have to wait long to see the results.

- Universal Use: The product works on all metal surfaces – from cars, agricultural machinery, and tools to metal fences and structures. It’s perfect for both professional workshops and home use.

2. Saves Time and Money

- No Need for Additional Products: Our rust neutralizer not only removes rust but also degreases the surface, so there’s no need to buy extra products.

- High Efficiency: One container covers a large surface, allowing you to save money and make the most of the product.

3. Safety and Eco-friendliness

- No Harmful Chemicals: Our product is free of dangerous chemicals, making it safe for the user and environmentally friendly.

- Long-lasting Protection: The neutralizer creates a protective layer on the surface, ensuring long-term rust prevention, which means less frequent maintenance.

4. Easy to Use

- Simple Application: The product can be applied with a brush, roller, spray, or any other tool – all you need to do is cover the rusted surface.

- Works on Closed Profiles: Ideal for hard-to-reach areas, such as closed car profiles, which are particularly prone to corrosion.

5. Proven and Recommended by Others

- Positive Customer Feedback: Many satisfied customers have shared videos and reviews confirming the effectiveness of our product.

- Trusted by Professionals: Our rust neutralizer is used by experts in various fields – from mechanics to restoration specialists.

6. Quality Guarantee

- Long-term Effectiveness: The product retains its properties even after a long time since opening – just shake it, and it’s ready to use.

- Return on Investment: By choosing our rust neutralizer, you’re investing in long-term protection for your equipment, saving on repair or replacement costs of rusted parts.

Rust Converter Blog Shorts YouTube

View all-

Rusty Water – Is It Safe to Drink? Risks & Safe...

Paweł JagieniakRusty Water – Is It Dangerous to Drink? 🥤🚱 What Causes Rusty Water? 🤔 Rusty water is usually caused by iron corrosion in old pipes. Over time, iron dissolves into...

Rusty Water – Is It Safe to Drink? Risks & Safe...

Paweł JagieniakRusty Water – Is It Dangerous to Drink? 🥤🚱 What Causes Rusty Water? 🤔 Rusty water is usually caused by iron corrosion in old pipes. Over time, iron dissolves into...

-

Incredible Rust Facts – Explosions, Bacteria & ...

Paweł JagieniakIncredible Rust Facts You Didn’t Know! 😲🔥 1️⃣ Rust Can Cause Explosions! 💥 Did you know that rust can lead to massive dust explosions? In grain or sugar silos, rusting...

Incredible Rust Facts – Explosions, Bacteria & ...

Paweł JagieniakIncredible Rust Facts You Didn’t Know! 😲🔥 1️⃣ Rust Can Cause Explosions! 💥 Did you know that rust can lead to massive dust explosions? In grain or sugar silos, rusting...

-

Shocking Facts About Rust in the USA! 🇺🇸😱 – The...

Paweł JagieniakThe Statue of Liberty is Rusting! 🗽☠️ The Statue of Liberty might look like solid copper, but its internal structure is actually steel. Over time, moisture and salty air cause...

Shocking Facts About Rust in the USA! 🇺🇸😱 – The...

Paweł JagieniakThe Statue of Liberty is Rusting! 🗽☠️ The Statue of Liberty might look like solid copper, but its internal structure is actually steel. Over time, moisture and salty air cause...

-

🚨 NYC’s Rusting Gas Pipes – A Disaster Waiting ...

Paweł Jagieniak🚨 A DISASTER THAT COULD STRIKE AT ANY MOMENT! ⚠️ New York City's Hidden Danger: Rusting Pipelines Beneath the Streets 🏙️ Beneath the streets of New York City lies over...

🚨 NYC’s Rusting Gas Pipes – A Disaster Waiting ...

Paweł Jagieniak🚨 A DISASTER THAT COULD STRIKE AT ANY MOMENT! ⚠️ New York City's Hidden Danger: Rusting Pipelines Beneath the Streets 🏙️ Beneath the streets of New York City lies over...

Restore Your Car's

In Your Car – Restore Your Car’s Sills, Fenders, and Suspension to Like-New Condition!

Rust on metal car parts, such as sills, fenders, or suspension components, can quickly lead to serious issues and expensive repairs. Chemikal States Rust Neutralizer is the perfect solution for removing rust from these critical areas. Our product effectively transforms rust into stable, insoluble compounds, preparing the surface for further painting and protection. This not only restores your vehicle's aesthetic appeal but also provides additional protection against future corrosion. Use Chemikal States to keep your car in excellent condition for years to come.

Why It’s Worth Protecting Your Car’s Undercarriage with a Rust Neutralizer

Applying a rust neutralizer to your car's undercarriage is an investment that offers numerous benefits. Here’s why it’s worth doing:

1. Protection Against Further Corrosion

The car’s undercarriage is especially exposed to external factors such as moisture, road salt, mud, and sand, which accelerate the rusting process. A rust neutralizer not only stops existing rust but also creates a protective barrier that prevents new damage from occurring.

2. Extends the Lifespan of Your Vehicle

If left untreated, rust can severely weaken your car’s structure, leading to costly repairs or even the need to replace entire parts of the undercarriage. By applying a rust neutralizer, you extend the life of your car’s undercarriage, allowing you to use your vehicle longer without worrying about its safety and structural integrity.

3. Saves on Repair Costs

Regularly protecting your car's undercarriage with a rust neutralizer saves you money in the long run. Rust-related repairs can be very expensive, especially when rust penetrates deep into the vehicle's structure. By investing in a neutralizer, you avoid these expenses and protect your undercarriage from costly damage.

Protect metal elements

In the Garden – Protect Metal Elements, Secure Your Lawn Mower, Metal Fencing, and Garage Roof from Rust

Garden elements like metal fences, trellises, and tools are exposed to moisture and varying weather conditions, which promotes rust formation. Chemikal States Rust Neutralizer performs exceptionally well in such conditions, effectively removing rust and preparing surfaces for painting. With it, your fence will look like new again, and your gardening tools will operate smoothly. Using Chemikal States ensures long-lasting protection for all your garden’s metal components.

In the garden, there are many elements worth protecting to extend their lifespan and safeguard them from rust and harsh weather conditions. Here’s a list of things you can protect:

1. Metal Fences and Gates

Metal fences and gates are exposed to moisture, rain, snow, and UV rays, which accelerate the rusting process. Protecting them with a rust neutralizer will prevent corrosion and keep them looking great for years.

2. Gazebos and Pergolas

If your gazebos or pergolas have metal parts in their construction, it's a good idea to protect them to prevent rust and damage. Applying a rust neutralizer shields these elements, ensuring the structure remains durable and weather-resistant.

3. Metal Garden Furniture

Tables, chairs, or garden benches made of metal are often exposed to rain and moisture. Protecting them from rust ensures you can use your furniture for longer without worrying about damage or frequent renovation.

Rust Converter DIY

In the Workshop – Essential for Metals Used in DIY Projects

If you're an avid DIYer or a professional craftsman, you know how important it is to keep your tools and materials in top condition. You don’t need me to tell you that! Chemikal States Rust Neutralizer is an indispensable product in your workshop. It excels at removing rust from hand tools, machinery, and equipment often exposed to moisture and contaminants. Our product effectively neutralizes rusty stains, allowing for precise preparation of surfaces for further work, painting, or coating. With Chemikal States, your tools will operate efficiently, and your DIY projects will proceed smoothly.

1. Creating Decorative Metal Planters

- Metal Buckets or Barrels: Transform old, rusty buckets or barrels into unique planters. Use the rust neutralizer to clean and treat the surface, then paint them in vibrant colors or add stencils for a personal touch, creating an eye-catching feature for your garden or patio.

2. Restoring and Protecting Your Outdoor Grill

- Grill Renovation: If your outdoor grill has developed rust, apply a rust neutralizer to clean its metal parts. This not only extends the lifespan of your grill but also ensures safer cooking by preventing contact with rusty surfaces. After treating, consider adding a coat of heat-resistant paint to give it a fresh, polished look.

Rust Converter: The Secret to Perfection That Will Impress Everyone

Rust Neutralizer is the perfect product for someone as exceptional as you. Your resourcefulness and attention to detail will make a huge impression on your family. Order now and show that you not only solve problems but also set standards that everyone admires. Your neighbors will look on with envy as your flawlessly executed work captures attention and makes your skills the benchmark for excellence!

I used the Rust Converter on my old metal fence, and it did an excellent job. It transformed the rusty areas into a solid, paintable surface with minimal effort. The process was quick and easy, and the end result looks fantastic. I highly recommend this product for anyone needing to tackle rust on metal.

I recently used a Rust Converter to restore my metal fence, and it worked great. The product effectively neutralized the rust, making the surface ready for painting. Application was straightforward, and it saved me a lot of time and effort compared to sanding. Overall, I’m really satisfied with the results and would recommend it for anyone dealing with rust on metal surfaces.

The product worked exactly as described, effectively neutralizing rust and converting it into a stable, paintable surface. This made the repair process much easier and faster.

Applying the converter was simple, and it quickly began to work on the rusted areas of the car's metal surfaces. In no time, the treated areas were ready for painting, with no need for extensive sanding or grinding. This product is an excellent solution for anyone dealing with rust on their vehicle.

I recently used the Rust Converter by Chemikal States, and I am genuinely impressed with its performance. The product works exactly as described. It effectively neutralizes rust and transforms it into a stable, paintable surface, saving both time and effort in rust removal and preparation.

The application was straightforward, and I appreciated how quickly the converter began to work. Within a short period, the rusted areas on my metal surfaces were stabilized and ready for the next steps in my project. This product is ideal for anyone looking to protect and extend the life of metal components without the need for extensive sanding or grinding.

Overall, the Rust Converter by Chemikal States is a reliable and effective solution for dealing with rust. It delivers on its promises and is definitely a product I would recommend to others.

Rust Neutralizer FAQ – Everything You Need to Know About Stopping Rust Effectively

What is a rust neutralizer, and how does it work?

A rust neutralizer is a chemical product designed to stop rust in its tracks by converting rust (iron oxide) into a stable, inert compound. It reacts with the rust to create a protective layer that prevents further oxidation, allowing you to paint or coat the surface without removing the rust entirely.

What is Rust Converter?

Rust Converter is a specialized chemical formula that transforms rust into a stable, non-rusting protective coating. It not only stops the corrosion process but also primes the surface for painting.

How does it work?

When applied to a rusty surface, Rust Converter reacts with iron oxides (rust) and converts them into a dark, protective layer. This new coating seals the metal from moisture and air, preventing further corrosion.

What surfaces can I use it on?

Rust Converter is ideal for use on iron and steel—perfect for fences, tools, automotive parts, metal structures, farm equipment, and more.

How do I use rust neutralizer on metal surfaces?

To use a rust neutralizer on metal surfaces, clean off any loose rust or debris with a wire brush. Apply the neutralizer evenly to the rusted areas, following the manufacturer’s instructions. Let it sit for the recommended time, allowing the chemical to react with the rust and create a protective barrier.

Metal corrosion is a process that affects various industries and aspects of everyday life, whether you’re a car owner, a construction engineer, or someone responsible for maintaining machinery. Corrosion can lead to costly repairs, equipment failures, and even catastrophic structural failures. Understanding how corrosion occurs, what causes it, and how to effectively prevent it is crucial for maintaining the integrity and longevity of metal structures and everyday items.

What Is Corrosion?

Corrosion is the gradual destruction of metals through chemical or electrochemical reactions with their environment. This process causes metals to deteriorate and lose their structural integrity and aesthetic appeal. The most common form of corrosion is rust, which specifically affects iron and steel. Rusting transforms the metal into oxides and hydroxides, such as rust (iron oxide), leading to the weakening and eventual failure of the material.

The Chemistry of Corrosion

Corrosion is essentially a redox reaction, where oxidation (loss of electrons) occurs at one part of the metal surface (the anode) and reduction (gain of electrons) occurs at another (the cathode). This process is particularly aggressive when metals are exposed to water and oxygen, creating an electrochemical cell on the metal's surface.

Oxidation at the Anode:

At the anode, metal atoms lose electrons and become positively charged ions. For example, when iron corrodes:

Fe→Fe2++2e−

Reduction at the Cathode:

The electrons released during the oxidation process travel through the metal to the cathode, where they reduce oxygen in the presence of water:

O2+2H2O+4e−→4OH−

These hydroxide ions then combine with the iron ions to form iron hydroxide, which further oxidizes to form rust:

Fe2++2OH−→Fe(OH)2→Fe2O3(rust)

Rust is porous and brittle, providing little to no protection to the underlying metal, which allows corrosion to continue until the metal is completely degraded.

Factors That Accelerate Corrosion

Several key factors can speed up or slow down the corrosion process:

-

Presence of Water and Oxygen: Water and oxygen are essential for the corrosion process. Even small amounts of moisture in the air can initiate rusting. This is why metals stored in humid environments corrode more rapidly.

-

Airborne Contaminants: Chemical compounds like sulfur dioxide (SO2) and chlorides, especially in coastal or industrial areas, can react with metals, accelerating the corrosion process. Saltwater environments are particularly harsh due to the high concentration of dissolved salts.

-

Temperature: Higher temperatures increase the rate of chemical reactions, including corrosion. In warmer climates, corrosion occurs more quickly because the increased temperature accelerates both the oxidation of metal and the diffusion of ions through any moisture present.

-

Metal Composition and Microstructure: The microstructure of the metal, including grain boundaries and impurities, can create localized anodic and cathodic areas, accelerating corrosion in certain spots. Alloy composition also plays a critical role in a metal's resistance to corrosion.

-

Mechanical Stress: Metals under mechanical stress are more prone to certain types of corrosion, such as stress corrosion cracking (SCC), which occurs when a metal under tensile stress in a corrosive environment begins to crack.

-

pH Levels: The acidity or alkalinity of the environment can also affect the rate of corrosion. Acidic environments (low pH) generally accelerate corrosion, while neutral or slightly alkaline environments tend to be less corrosive.

Types of Corrosion

Corrosion manifests in various forms, depending on environmental conditions and the type of metal:

-

Uniform Corrosion: This type of corrosion occurs evenly across the surface of the metal, leading to a consistent thinning of the material. It’s predictable and easier to manage compared to other forms of corrosion.

-

Localized Corrosion (Pitting): Pitting is a highly localized form of corrosion that creates small holes or pits in the metal. These pits can penetrate deep into the metal, causing significant structural damage while leaving much of the surface intact.

-

Galvanic Corrosion: This occurs when two different metals are in electrical contact in the presence of an electrolyte (such as water). The more reactive metal (anode) corrodes faster, while the less reactive metal (cathode) is protected.

-

Intergranular Corrosion: This form of corrosion occurs along the grain boundaries within the metal. It often happens in alloys where one element in the alloy preferentially corrodes, leading to a weakening of the material along these boundaries.

-

Stress Corrosion Cracking (SCC): SCC occurs when a metal is subjected to tensile stress in a corrosive environment. This type of corrosion leads to the formation of cracks, which can propagate and lead to sudden and catastrophic failures.

-

Crevice Corrosion: This type of corrosion occurs in confined spaces where the concentration of corrosive agents, such as chlorides, becomes high. Examples include the areas under gaskets, lap joints, or deposits on the metal surface.

-

Erosion Corrosion: This occurs when a corrosive fluid flows over a metal surface at high speed, physically removing the protective oxide layer and exposing the underlying metal to further corrosion.

-

Microbiologically Influenced Corrosion (MIC): MIC is caused by the presence of microorganisms, such as bacteria, algae, or fungi, which produce corrosive byproducts like acids or sulfides. This is common in pipelines, water systems, and marine environments.

Preventing Corrosion

Given the wide range of factors that can cause and accelerate corrosion, effective prevention requires a multifaceted approach. Here are some of the most effective methods to prevent corrosion:

-

Protective Coatings: Applying paints, varnishes, or specialized anti-corrosion coatings can significantly reduce corrosion by creating a barrier that prevents moisture and oxygen from reaching the metal surface. Common coatings include epoxy, polyurethane, and powder coatings.

-

Galvanization: This process involves coating steel or iron with a layer of zinc, which acts as a sacrificial anode. Zinc corrodes instead of the underlying metal, providing long-term protection. Galvanized steel is commonly used in outdoor applications and for structures exposed to harsh environments.

-

Cathodic Protection: This technique involves connecting the metal to be protected to a more easily corroded "sacrificial" metal. This sacrificial metal acts as the anode and corrodes instead of the protected metal. This method is widely used in pipelines, underground tanks, and marine structures.

-

Corrosion Inhibitors: These are chemicals added to a fluid or gas that surrounds the metal, reducing the rate of corrosion. Inhibitors work by forming a protective film on the metal surface or by neutralizing the corrosive elements in the environment.

-

Material Selection: Using corrosion-resistant materials, such as stainless steel, aluminum, or special alloys, can prevent corrosion from occurring. These materials are designed to resist oxidation and other forms of chemical attack.

-

Environmental Control: Reducing humidity, controlling temperature, and minimizing exposure to corrosive substances can help prevent corrosion. In industrial settings, dehumidifiers, ventilation systems, and controlled environments are commonly used.

-

Regular Maintenance and Inspection: Routine inspection and maintenance are critical in detecting early signs of corrosion and taking corrective action before significant damage occurs. Regular cleaning and reapplication of protective coatings can extend the life of metal structures.

-

Design Modifications: Engineers can design structures to minimize crevices, sharp corners, and other areas where corrosive agents might accumulate. Ensuring proper drainage and avoiding stagnant water can also reduce the risk of corrosion.

How to Effectively Stop Corrosion? – Our Solution

At Chemikal States, we understand the challenges that corrosion poses and how important it is to stop it before it causes significant damage. That's why we offer the Chemikal States Rust Converter – a product designed to effectively halt the corrosion process and protect metal from further degradation.

Why Choose Our Rust Converter?

-

Effectiveness: Our Rust Converter works by chemically converting rust into a stable, protective layer that not only stops corrosion but also primes the surface for painting or further treatment.

-

Ease of Use: The product is easy to apply. Whether using a brush, roller, or spray, the fast-drying formula allows for quick and efficient protection of the surface.

-

Safety: Chemikal States Rust Converter is safe for both the user and the environment. It does not contain harsh chemicals, making it a responsible choice for various applications.

-

Versatility: Our Rust Converter is suitable for use on a wide range of metal surfaces, including vehicles, tools, construction structures, and fences. It’s an all-in-one solution for various industries.

-

Long-lasting Protection: Once applied and dried, the Chemikal States Rust Converter forms a durable protective layer that shields metal from further exposure to moisture, contaminants, and other corrosive agents.

-

Cost-Effectiveness: By preventing further corrosion, our Rust Converter helps extend the life of metal structures and equipment, reducing the need for costly repairs and replacements. It’s a smart investment in long-term durability.

Don’t Let Corrosion Destroy Your Metal

Corrosion is a relentless force that can quickly degrade metal surfaces, leading to structural weaknesses, equipment failures, and even safety hazards. But you don’t have to let corrosion win. By choosing Chemikal States Rust Converter, you’re investing in a proven solution that provides long-lasting protection against corrosion. Don’t wait until it’s too late—take action now to preserve and protect your metal assets.

Ready to Protect Your Metal?

Explore our range of corrosion protection products, and discover how Chemikal States can help you fight back against corrosion. Whether you’re dealing with rusty tools, vehicles, or industrial structures, our Rust Converter offers the protection you need to keep your metal in top condition.

Contact us today to learn more about our products and how they can help you effectively combat corrosion. Together, we can ensure that corrosion doesn’t stand a chance!

Do I need to remove rust before applying it?

No. Just remove any loose rust with a wire brush or sandpaper. Rust Converter works best on lightly to moderately rusted surfaces.

What’s the difference between rust neutralizer and rust remover?

Rust neutralizer converts rust into a stable surface, allowing for painting or coating without removing the rust, while rust remover completely eliminates rust by chemically dissolving it. Rust neutralizers are ideal for situations where complete rust removal isn’t practical or necessary.

How long does it take to dry?

Under standard conditions, it dries to the touch in about 20 minutes and fully cures in approximately 24 hours.

Do I need to paint over it afterward?

Painting is not required but is recommended—adding a paint layer enhances long-term protection. Rust Converter creates a surface that’s ready for painting.

Is the product environmentally friendly?

Yes, Rust Converter is water-based and solvent-free, making it safer for both the user and the environment.

How long does rust neutralizer take to work?

Rust neutralizer typically takes 15 to 30 minutes to fully react with the rust. After this period, the rust will turn into a black or dark layer, indicating that it has been neutralized. You can then proceed with priming or painting the surface for long-term protection.

Can I paint over rust neutralizer?

Yes, after applying rust neutralizer and allowing it to dry, you can paint over the treated surface. The neutralizer creates a protective layer over the rust, making it easier to apply a primer or paint without worrying about the rust continuing to spread beneath the surface.

Is rust neutralizer safe to use on cars?

Yes, rust neutralizer is safe to use on cars. It’s commonly used in automotive restoration to stop rust on car bodies and undercarriages before applying paint or protective coatings. Ensure the area is clean and dry before applying the product for the best results.

Can rust neutralizer prevent future rusting?

Rust neutralizer helps prevent future rusting by converting rust into a stable, non-corrosive compound. However, it’s important to apply a primer or protective coating over the neutralized rust to fully prevent future exposure to moisture, which can cause rust to return.

What is the best rust neutralizer for metal?

The best rust neutralizer for metal is one that reacts quickly and creates a strong protective layer, like Chemikal States Rust Neutralizer. It penetrates deep into the rust, ensuring complete neutralization and preparing the surface for painting or coating.

Does rust neutralizer work on painted surfaces?

Rust neutralizer works best on exposed, rusted metal surfaces. If rust is forming underneath paint, the paint may need to be sanded or removed to allow the neutralizer to properly contact the rust. Applying rust neutralizer over paint may not yield the best results.

Can I use rust neutralizer on tools?

Yes, rust neutralizer can be used on tools to stop rust from spreading and restore their appearance. Simply apply the product to the rusted areas, let it work, and wipe off any excess before applying a protective oil or coating to keep the tools rust-free.

How long does rust neutralizer last once applied?

Rust neutralizer can last indefinitely if it’s followed by a protective coating like paint, primer, or a sealant. The neutralized rust forms a stable layer that won’t continue to corrode as long as it’s protected from further exposure to moisture and air.

Can rust neutralizer be used on stainless steel?

Rust neutralizer is typically used on carbon steel and iron surfaces, not on stainless steel. Stainless steel is more resistant to rust due to its chromium content, and any rust that does form should be treated with products specifically designed for stainless steel surfaces.

Is rust neutralizer better than sanding off rust?

Rust neutralizer can be more efficient than sanding, especially in areas with heavy rust or hard-to-reach spots. Sanding removes rust mechanically, while neutralizer chemically transforms it into a stable compound. Combining both methods can offer the best results for heavily rusted surfaces.

Can I use rust neutralizer indoors?

Yes, rust neutralizer can be used indoors, but ensure the area is well-ventilated, as some products may release fumes during the chemical reaction. Always follow the safety instructions on the label when using indoors.

Does rust neutralizer remove rust stains?

Rust neutralizer is designed to neutralize rust on metal surfaces but may not remove rust stains on non-metal surfaces like concrete or fabric. For rust stains, you’ll need a rust remover or stain treatment product designed specifically for those surfaces.

Can I use rust neutralizer on outdoor metal structures?

Yes, rust neutralizer is highly effective for outdoor metal structures like fences, gates, and garden tools. After neutralizing the rust, it’s important to apply a weatherproof coating or paint to protect the metal from future rust caused by outdoor elements.

How often should I reapply rust neutralizer?

Rust neutralizer generally only needs to be applied once to a rusted surface. However, if the surface is exposed to harsh conditions or moisture, it’s important to follow up with a protective coating to ensure long-lasting results and prevent rust from reappearing.

Can I use rust neutralizer on iron gates?

Yes, rust neutralizer is ideal for iron gates, where rust commonly forms due to exposure to the elements. Applying rust neutralizer will stabilize the rust and prevent further corrosion, making it easier to paint and protect the gate from future rusting.

Is rust neutralizer flammable?

Most rust neutralizers are water-based and non-flammable, but it’s important to check the label for specific product details. Avoid using rust neutralizer near open flames or heat sources, and always follow safety precautions during application.

What is the best way to apply rust neutralizer?

The best way to apply rust neutralizer is with a brush or spray, depending on the size of the area. Ensure the surface is clean, free from loose rust, and dry. Apply the product evenly across the rusted surface, allowing it to fully react and dry before painting or coating.

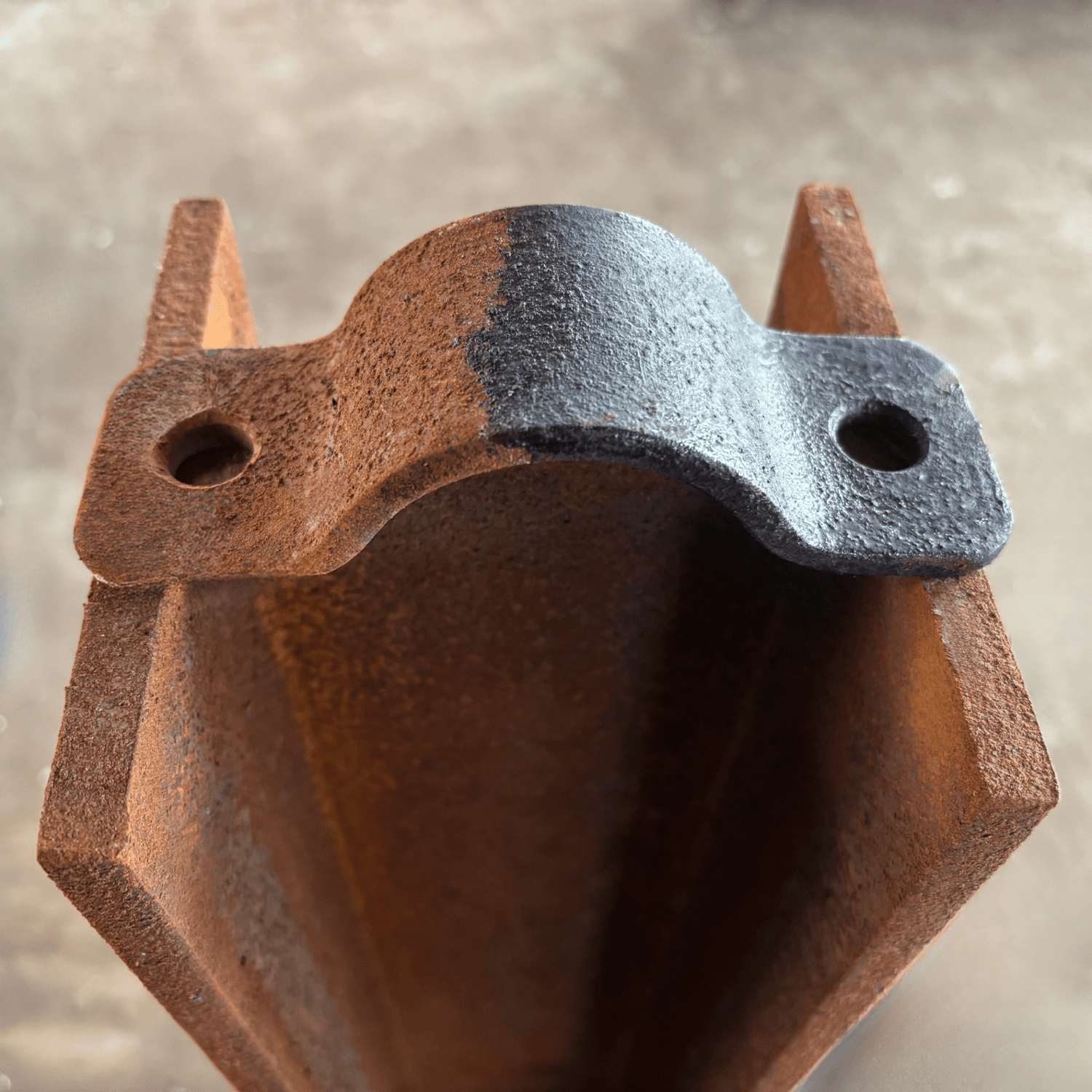

Can I use rust neutralizer on cast iron?

Yes, rust neutralizer works effectively on cast iron surfaces. Cast iron is prone to rust, especially when exposed to moisture, making rust neutralizer a great option to stop rust and protect the metal. Be sure to apply a protective oil or coating after treatment for long-lasting results.

Does rust neutralizer change the color of metal?

Rust neutralizer typically turns rusted areas black or dark brown, indicating that the rust has been neutralized. This color change does not affect the metal itself and can be easily covered with paint or primer if needed.

How long should I wait before painting over rust neutralizer?

You should wait until the rust neutralizer has fully dried and the rusted area has been converted into a stable layer. This typically takes about 30 minutes to a few hours, depending on the product and environmental conditions. Once dry, you can apply primer or paint.

Can I use rust neutralizer on small rust spots?

Yes, rust neutralizer is effective for treating both small rust spots and larger areas. Simply apply the product to the rust spot, let it react, and then wipe away any excess. This will stop the rust from spreading and prepare the surface for painting or coating.

Is rust neutralizer toxic?

Most rust neutralizers are non-toxic and safe for use when handled properly, but it’s important to follow the safety instructions on the label. Wear gloves and eye protection, and ensure adequate ventilation when using the product indoors to avoid inhaling any fumes.

Can rust neutralizer be used on aluminum?

Rust neutralizer is not typically used on aluminum, as aluminum does not rust in the same way that iron or steel does. If aluminum surfaces are corroded, a product specifically designed for aluminum corrosion should be used instead.

Can I use rust neutralizer before welding metal?

Yes, rust neutralizer can be used before welding to stabilize rusted metal and ensure a cleaner surface for welding. However, it's important to remove any excess product and ensure the metal is dry before welding, as residue could interfere with the welding process.

What is the best rust neutralizer for metal surfaces?

The best rust neutralizer for metal surfaces is one that quickly converts rust into a stable compound and prepares the surface for painting or coating. Chemikal States Rust Neutralizer is highly rated for its ability to penetrate rust deeply, creating a protective layer that prevents future corrosion.

Can I use rust neutralizer on cars?

Yes, rust neutralizer is safe to use on cars. It is often used to treat rust on car bodies, undercarriages, and frames before applying paint or a protective coating. Always ensure the rusted area is cleaned before applying the neutralizer.

How long does rust neutralizer take to work?

Rust neutralizer typically takes between 15 and 30 minutes to fully convert rust into a stable compound. After this time, you can proceed with applying primer or paint to the treated surface for long-term protection.

Do I need to remove all the rust before applying a rust neutralizer?

No, you do not need to remove all the rust before applying a rust neutralizer. The neutralizer works by chemically converting rust into a non-reactive compound. However, it's important to remove any loose, flaky rust with a wire brush before applying the product for the best results.

Can rust neutralizer be used on stainless steel?

Rust neutralizers are typically used on iron and carbon steel, but they are not recommended for stainless steel. Stainless steel is resistant to rust due to its chromium content, and if rust does appear, it is best treated with a product designed specifically for stainless steel.

What is the difference between rust neutralizer and rust remover?

Rust neutralizer converts rust into a stable compound, allowing you to paint or coat over it, while rust remover completely eliminates rust by dissolving it chemically. Rust neutralizers are ideal for situations where complete rust removal is not feasible or necessary.

Can I paint over rust neutralizer?

Yes, you can paint over rust neutralizer once it has dried and the rust has been converted into a stable, protective layer. This allows for better adhesion of primers and paints, ensuring long-term protection against future rust.

How long does rust neutralizer last?

Rust neutralizer can last indefinitely as long as it is followed by a protective coating such as paint, primer, or a sealant. The neutralized rust forms a stable layer that prevents further corrosion, provided it is not exposed to moisture or air.

Does rust neutralizer prevent future rusting?

Rust neutralizer helps prevent future rusting by converting existing rust into a stable, non-corrosive compound. However, for complete protection, it's crucial to apply a primer or rust-resistant paint to the treated surface to shield it from moisture and air.

Can I use rust neutralizer on tools?

Yes, rust neutralizer can be applied to tools to stop rust from spreading and restore their usability. After neutralizing the rust, it's recommended to apply a protective coating or oil to keep the tools rust-free in the future.

What is the best way to apply rust neutralizer?

The best way to apply rust neutralizer is with a brush or spray. First, remove any loose rust using a wire brush, then apply the neutralizer evenly to the rusted area. Let it sit for the recommended time before proceeding with primer or paint.

Can rust neutralizer be used on outdoor metal structures?

Yes, rust neutralizer is highly effective on outdoor metal structures such as fences, gates, and garden tools. Once the rust has been neutralized, it’s important to apply a weatherproof coating to protect the metal from future rust caused by moisture and outdoor elements.

Is rust neutralizer flammable?

Most rust neutralizers are water-based and non-flammable. However, it's important to check the specific product label for safety information. Always follow the manufacturer’s guidelines, especially when applying near open flames or heat sources.

Does rust neutralizer change the color of metal?

Rust neutralizer typically turns rusted areas into a black or dark brown color, indicating that the rust has been neutralized. This color change doesn't affect the metal and can be easily covered with primer or paint.

How do I use rust neutralizer on small rust spots?

Rust neutralizer can be used on small rust spots by applying the product directly to the affected area. After the rust is neutralized, you can wipe away any excess and apply paint or a protective coating to prevent further rusting.

Is rust neutralizer toxic?

Most rust neutralizers are non-toxic when used properly, but it's always important to follow the safety instructions on the product label. Wear gloves and ensure good ventilation when applying indoors to avoid inhaling any fumes.

FAQ posts

-

Rust Converter FAQ – Everything You Need to Know

General Questions What is a rust converter? A rust converter is a chemical solution that reacts with rust (iron oxide) and transforms it into a stable, black protective coating. This...

Rust Converter FAQ – Everything You Need to Know

General Questions What is a rust converter? A rust converter is a chemical solution that reacts with rust (iron oxide) and transforms it into a stable, black protective coating. This...