What Are the Different Types of Concrete and Their Uses?

Share

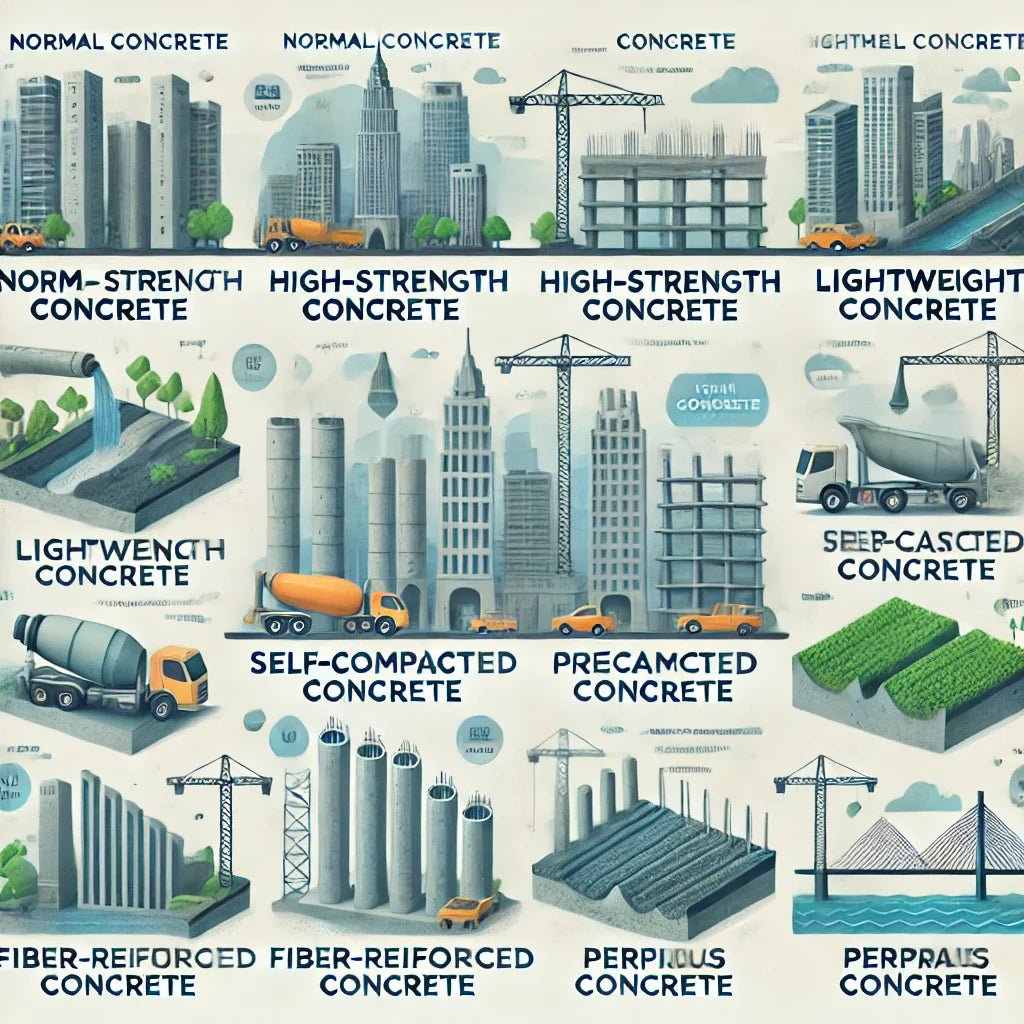

Concrete is one of the most versatile building materials used worldwide, thanks to its durability, strength, and adaptability to different environments. Depending on the specific requirements of a project, various types of concrete are designed to meet the needs of construction, from residential buildings to large infrastructure projects. Below, we explore the most common types of concrete and their applications.

1. Normal Concrete

✅ Composition: Cement, sand, gravel, and water. ✅ Features: Moderate strength, easy to work with, and widely available. ✅ Common Uses: Foundations, sidewalks, driveways, and general construction.

2. High-Strength Concrete

✅ Composition: High-quality cement, silica fume, fine aggregates, and superplasticizers. ✅ Features: Higher compressive strength (>6,000 psi), durable, resistant to harsh weather conditions. ✅ Common Uses: Skyscrapers, bridges, and heavy-load structures.

3. Lightweight Concrete

✅ Composition: Cement, lightweight aggregates (expanded clay, perlite, or pumice). ✅ Features: Reduced weight, good thermal insulation, and sound absorption. ✅ Common Uses: Prefabricated building panels, insulation layers, and lightweight roofing structures.

4. Reinforced Concrete (RC)

✅ Composition: Normal concrete with steel bars (rebars) or wire mesh reinforcement. ✅ Features: Increased tensile strength and durability. ✅ Common Uses: Bridges, foundations, columns, and structural elements of high-rise buildings.

5. Prestressed Concrete

✅ Composition: Concrete with high-tensile steel tendons pre-tensioned before pouring. ✅ Features: Higher load-bearing capacity, reduced cracking, and longer spans without support columns. ✅ Common Uses: Highways, bridges, railway sleepers, and large-scale infrastructure projects.

6. Precast Concrete

✅ Composition: Concrete cast and cured in a factory setting before being transported to a construction site. ✅ Features: High precision, faster construction, and reduced labor costs. ✅ Common Uses: Prefabricated walls, beams, stairs, pipes, and structural components.

7. Self-Compacting Concrete (SCC)

✅ Composition: Cement, fine aggregates, superplasticizers, and viscosity-modifying agents. ✅ Features: High flowability without mechanical vibration, reduced labor, and smooth surface finish. ✅ Common Uses: Dense reinforcement structures, architectural elements, and high-rise buildings.

8. High-Performance Concrete (HPC)

✅ Composition: High-quality cement, silica fume, fly ash, and chemical admixtures. ✅ Features: Enhanced strength, durability, and resistance to extreme weather. ✅ Common Uses: Marine structures, nuclear plants, tunnels, and bridges.

9. Fiber-Reinforced Concrete (FRC)

✅ Composition: Cement, aggregates, water, and fibers (steel, glass, polypropylene, or carbon fibers). ✅ Features: Increased tensile strength, impact resistance, and reduced cracking. ✅ Common Uses: Industrial flooring, earthquake-resistant structures, and pavements.

10. Pervious Concrete (Porous Concrete)

✅ Composition: Cement, coarse aggregates, water, and minimal fine aggregates. ✅ Features: Allows water drainage, reduces runoff, and is eco-friendly. ✅ Common Uses: Parking lots, sidewalks, stormwater drainage systems, and sustainable construction.

Final Thoughts

Each type of concrete has unique properties that make it suitable for specific construction needs. Whether it's reinforced concrete for skyscrapers, pervious concrete for eco-friendly drainage, or self-compacting concrete for complex designs, understanding the differences can help choose the right material for the job.

📌 Looking to keep your concrete surfaces clean and free from oil stains? Check out our best-selling Oil Remover Solution for professional cleaning solutions!